3D printers in the automotive industry

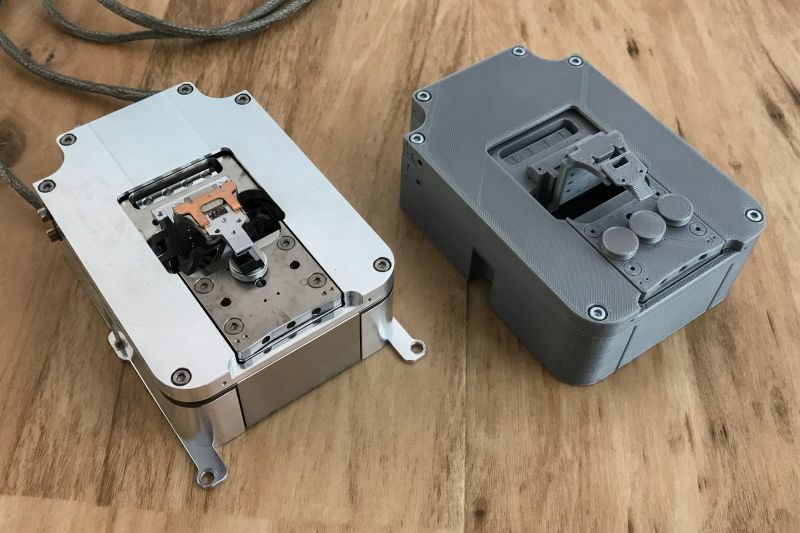

Vibracoustic case study

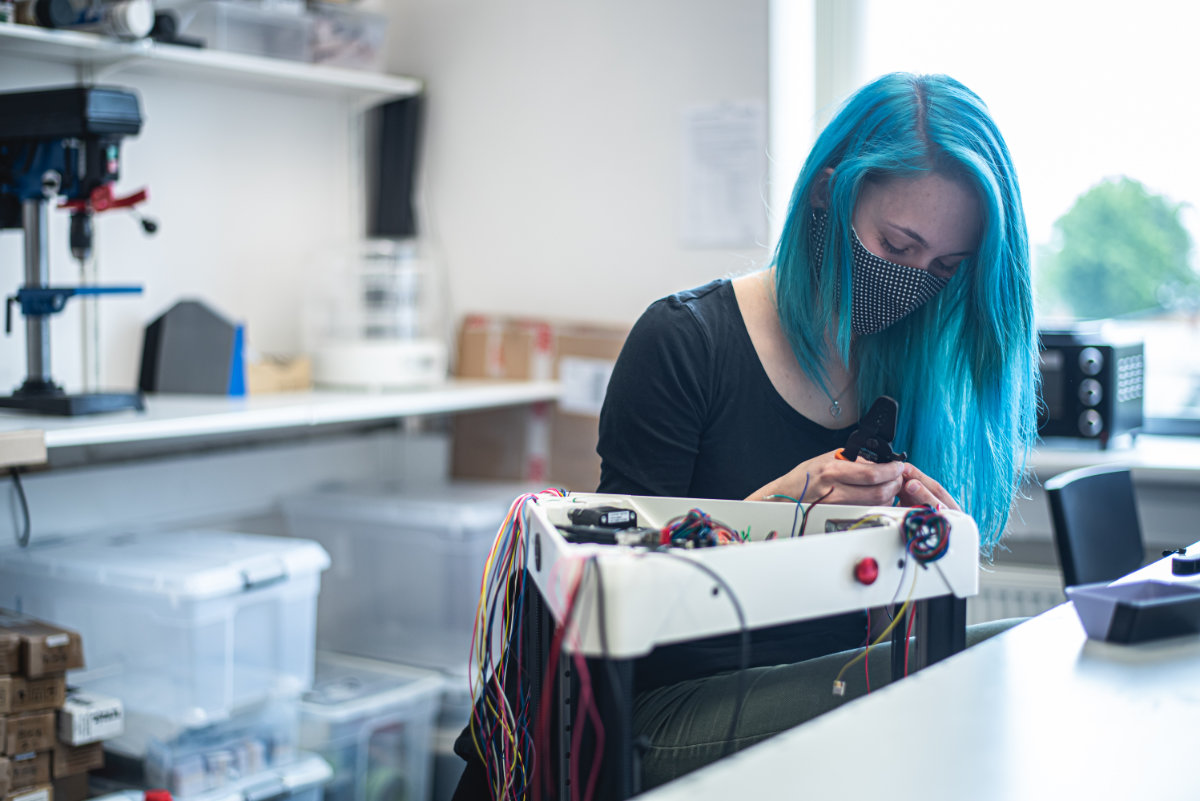

Case studies

Take a look at some of the stories of our customers and partners. In the case studies, you will most likely find problems and solutions you come across regularly during production. A 3D printer will shorten the length of time and lower expenses regarding production and prototype creation.

BlackPrint

Accessories for airsoft equipment with a specially modified TRILAB printer.

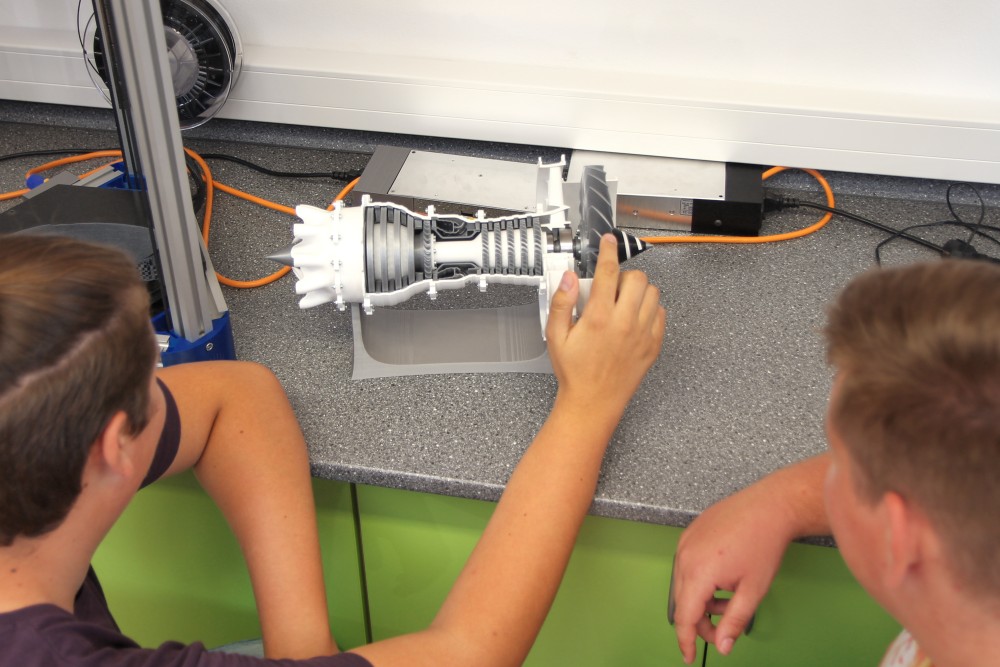

Nirvana Systems

TRILAB printers help with the development of paramotors and rotorcraft.

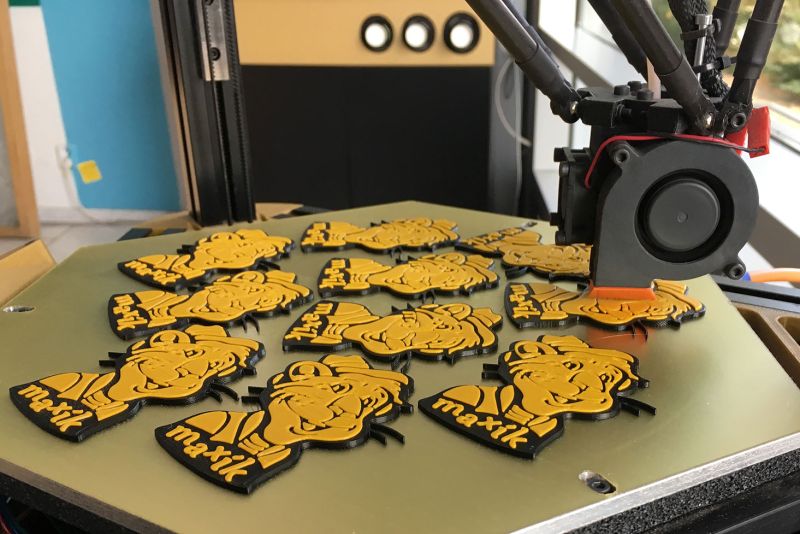

Havas

The 3D printer attracts both young and older generations and creates great promotional items.

Adam Krhánek

“Cybersculptor", who created the largest 3D printed sculpture in Europe.

NenoVision

How to touch something that is forbidden to be touched? Using 3D printing!

All these organizations are already saving because of TRILAB 3D printers

Our precision 3D printers

When purchasing a 3D printer from TRILAB, you won't simply end up with a box of hardware. We're here to support you and even provide training so you can fully take advantage of that precisely built machine.

TRILAB AzteQ Dynamic

The TRILAB AzteQ Dynamic professional delta printer is the ideal workhorse for high-volume printing of PLA, PETG, PA-CF or PC-CF and meets the requirements of customers who appreciate the versatility of the AzteQ series, superior surface quality, high print volume but do not require an actively heated print chamber.

TRILAB AzteQ Industrial

This professional delta printer features a closed printing chamber for exceptional 3D printing without material or spatial compromises. The swappable magnetic printhead is equipped with an auto-calibrated strain gauge allowing for even easier 3D printing.

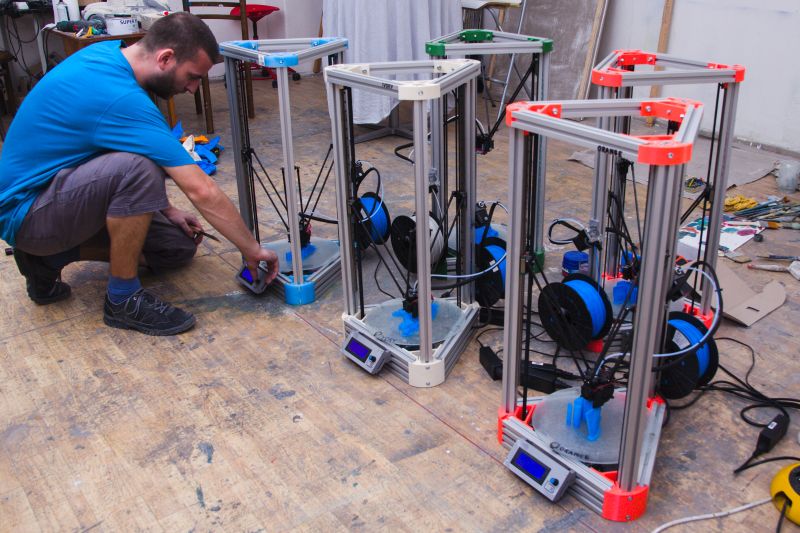

Made and tuned in the Czech Republic

DeltiQ printers are the direct result of the cooperation of our development and production teams. Subsequent real testing and output control give you the assurance that you will get a perfectly tuned machine.

68 parameters

Only perfectly tuned machines pass our demanding output control.

1,4 kg

The amount of material used during testing.