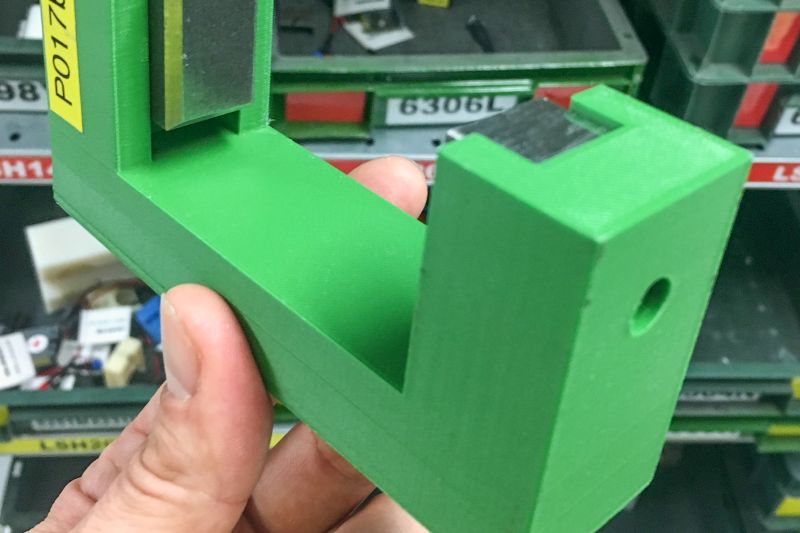

Jigs and tools at 90 % the cost and instantly available

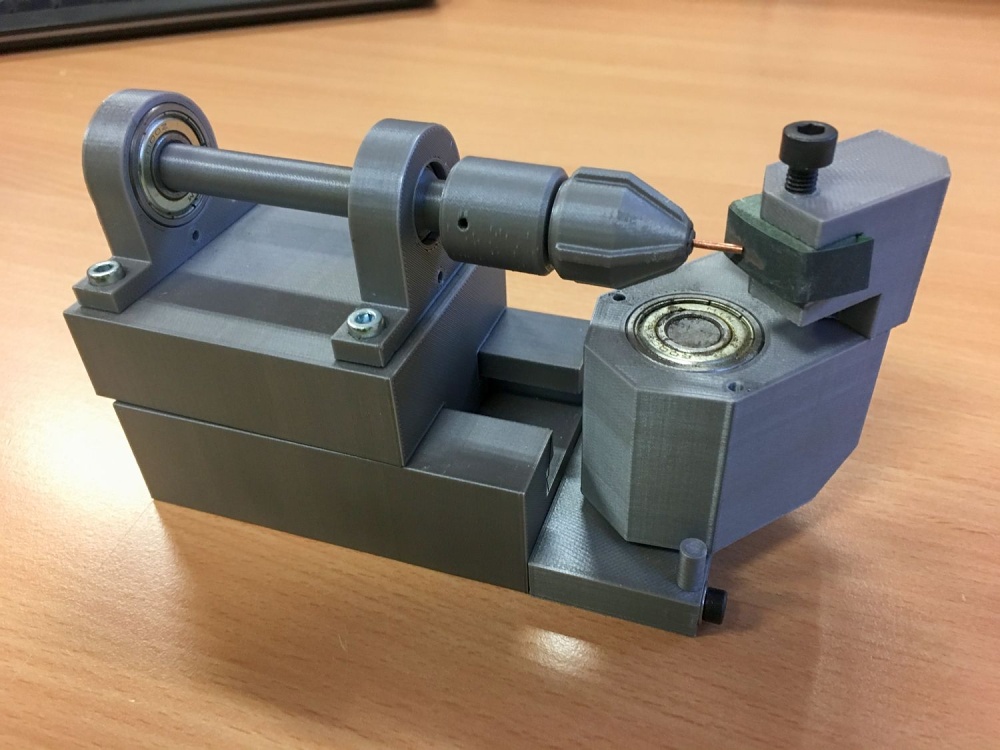

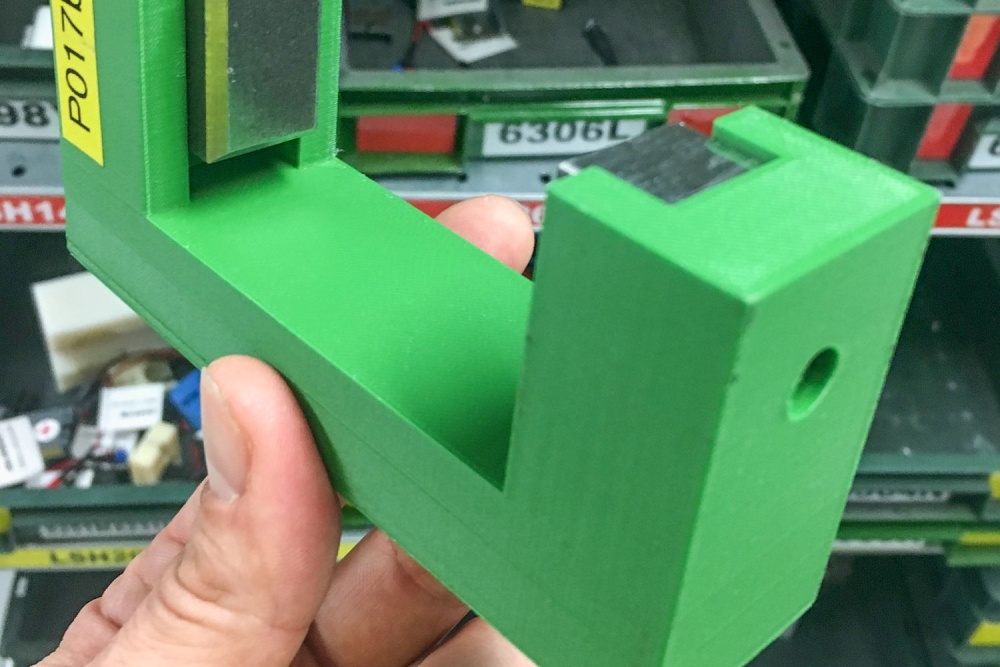

Whether you need a specialized holder shape or a calibration tool, 3D jig printing always translates to a dimensionally accurate product.

The use of TRILAB

3D printers in production

The entire process of developing, optimizing and producing jigs and tools directly on your own 3D printer is incomparably faster when compared to an injection molding machine or casting. You’ll suddenly discover areas where you can make work easier for both your colleagues and you, for a fraction of the price.

Accuracy

Dimensional accuracy with less than a 0.5 % error margin

Print size

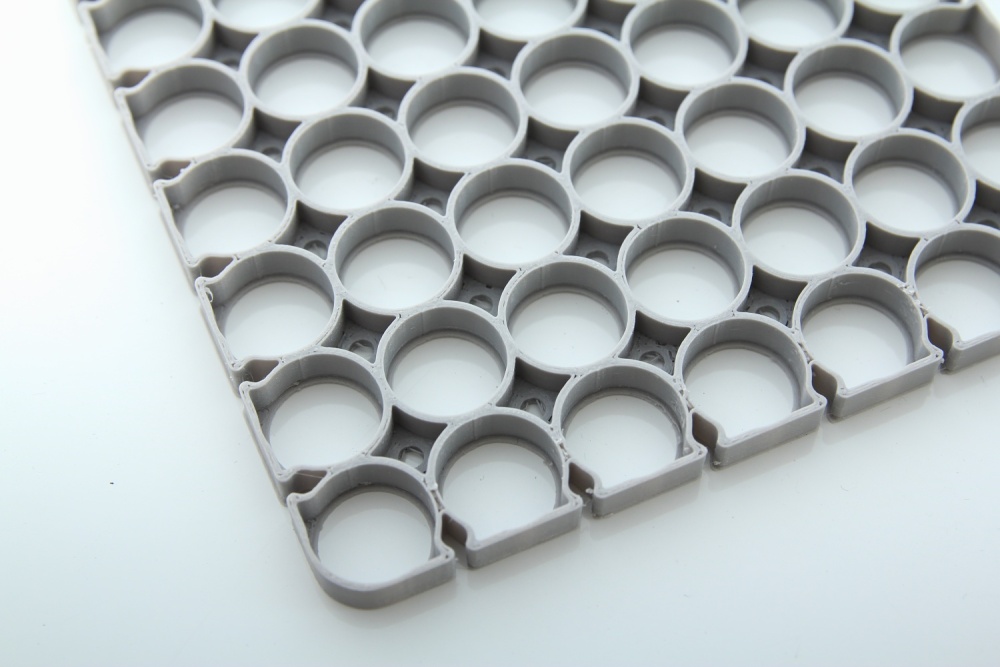

Large print volume and print height up to 50 cm

Less supports

Overhangs and long bridge supports are printable and a minimum amount of them are needed

Tuned printer

You get a dialed in tool for rapid prototype creation

Superb service

You’ll receive personalized service and support

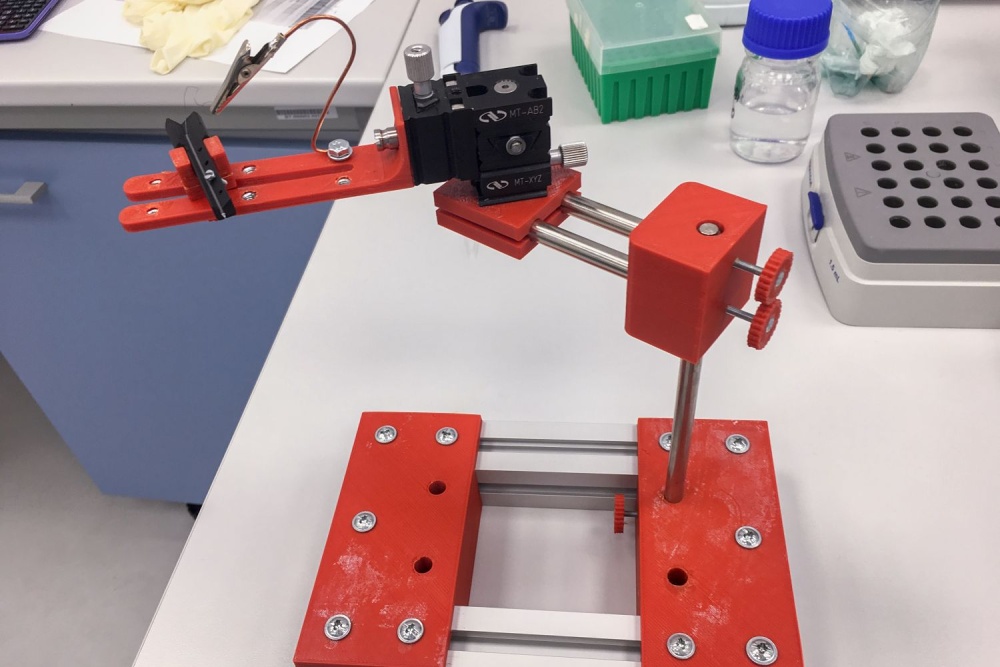

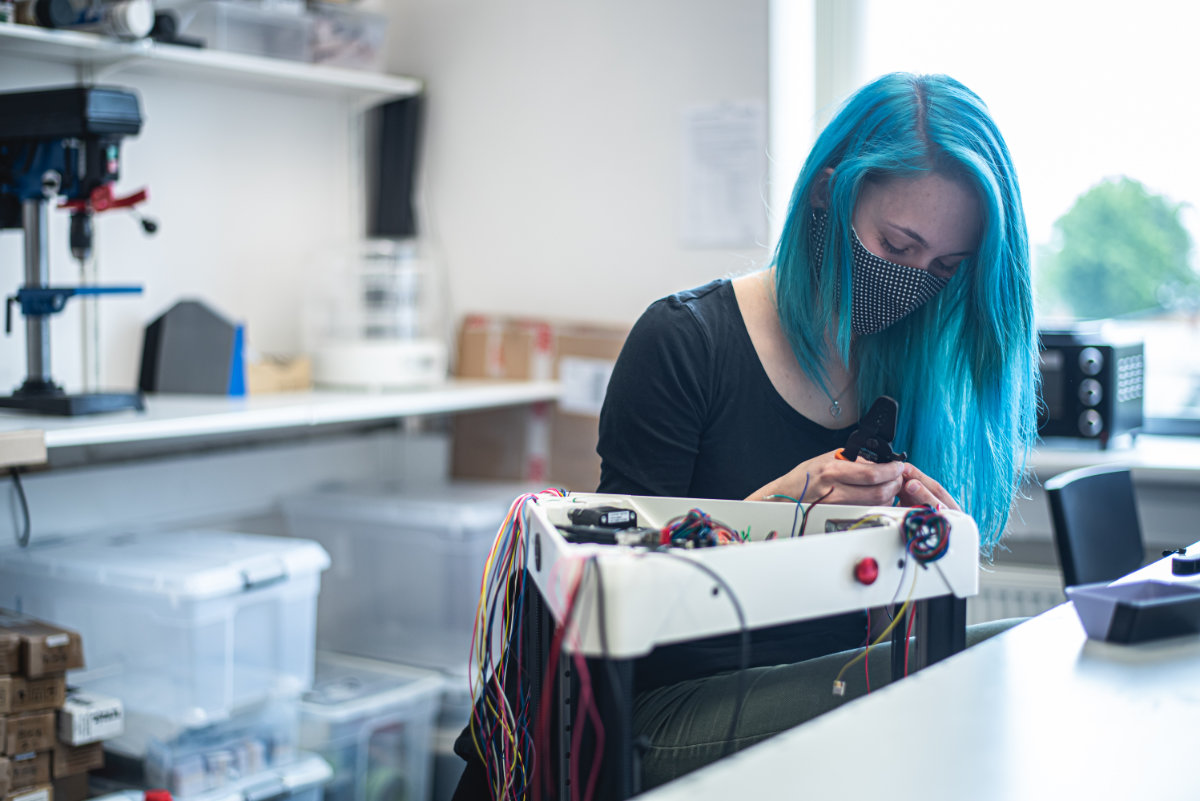

How are companies using TRILAB printers for their own prototypes?

Our printers are already engaged here

Our precision 3D printers

When purchasing a 3D printer from TRILAB, you won't simply end up with a box of hardware. We're here to support you and even provide training so you can fully take advantage of that precisely built machine.

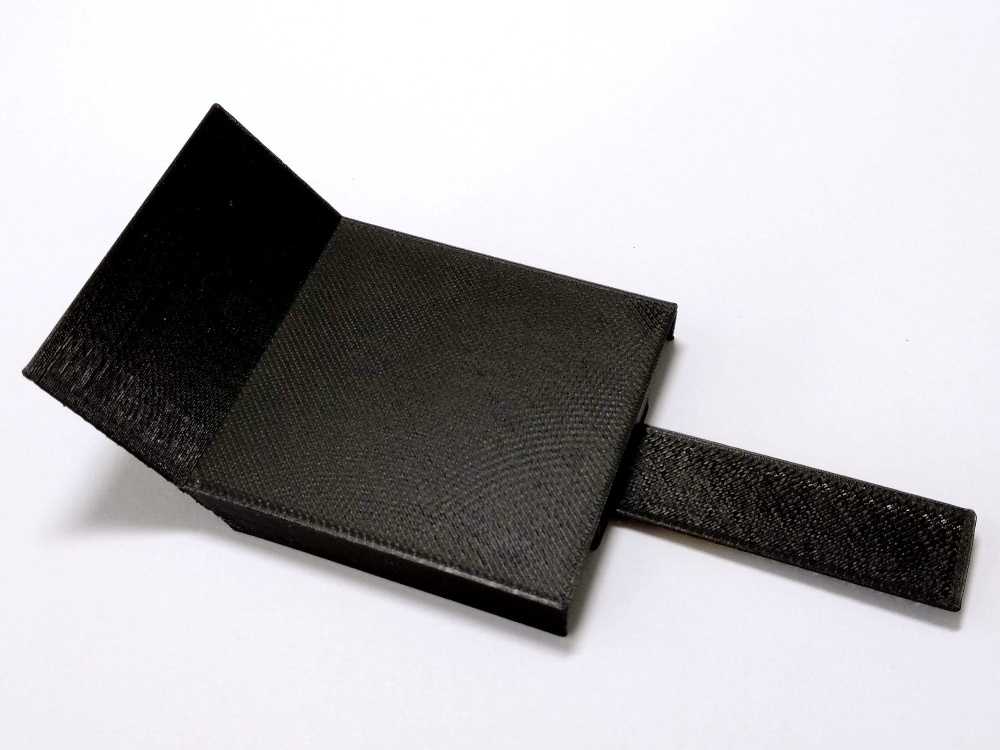

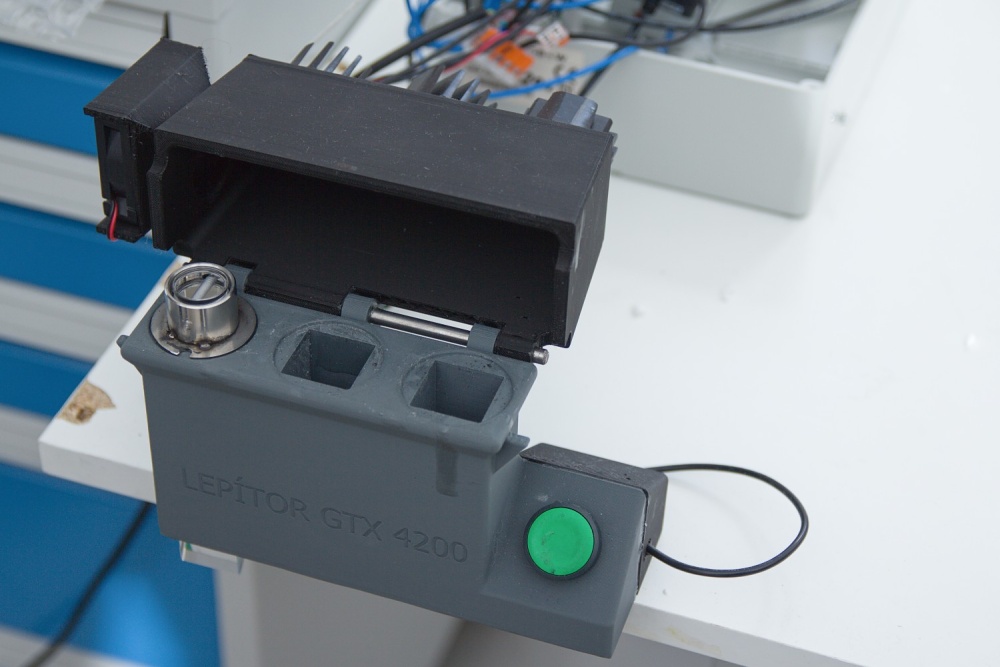

TRILAB AzteQ Industrial

This professional delta printer features a closed printing chamber for exceptional 3D printing without material or spatial compromises. The swappable magnetic printhead is equipped with an auto-calibrated strain gauge allowing for even easier 3D printing.

Made and tuned in the Czech Republic

DeltiQ printers are the direct result of the cooperation of our development and production teams. Subsequent real testing and output control give you the assurance that you will get a perfectly tuned machine.

68 parameters

Only perfectly tuned machines pass our demanding output control.

1,4 kg

The amount of material used during testing.