3D printing in automotive and manufacturing

Create a 3D model and use the new tooling on the production lines the next day

See how 3D printing is being used by other companies in the automotive and industrial manufacturing industries. Examples of specific prints, as well as descriptions of 3D printing implementations, may inspire you to imagine how additive manufacturing could specifically help your company.

Automotive companies printing with TRILAB

Quick and easy 3D printing with TRILAB

1 3D Printing With the Click of a Button

Our preset material-specific profiles enable you to print instantaneously and with zero errors through a user-friendly web interface.

2 Prints for Demanding Applications

Our printers can produce components for demanding applications, offering strength, lightness, flexibility as well as temperature and chemical resistance.

3 Training and Support Services Included

We deliver our machines as a complete solution, fine-tuned and tested, with installation, initial training, and user support included in our service package.

4 Accuracy of delta kinematics

In addition to their printing speed, the main advantages of delta printers are their high spatial accuracy and superior printing surface quality.

5 Remote printer management

With integrated lighting, a built-in camera and remote access from anywhere, you have 100% control of the printer. Now you can print for days without worries or let our technicians check your printer quickly and safely.

6 Additional features for efficient 3D printing

TRILAB 3D printers have, for example, swappable PrintHeads, swappable PrintPad sheets or the DeltaControl control display.

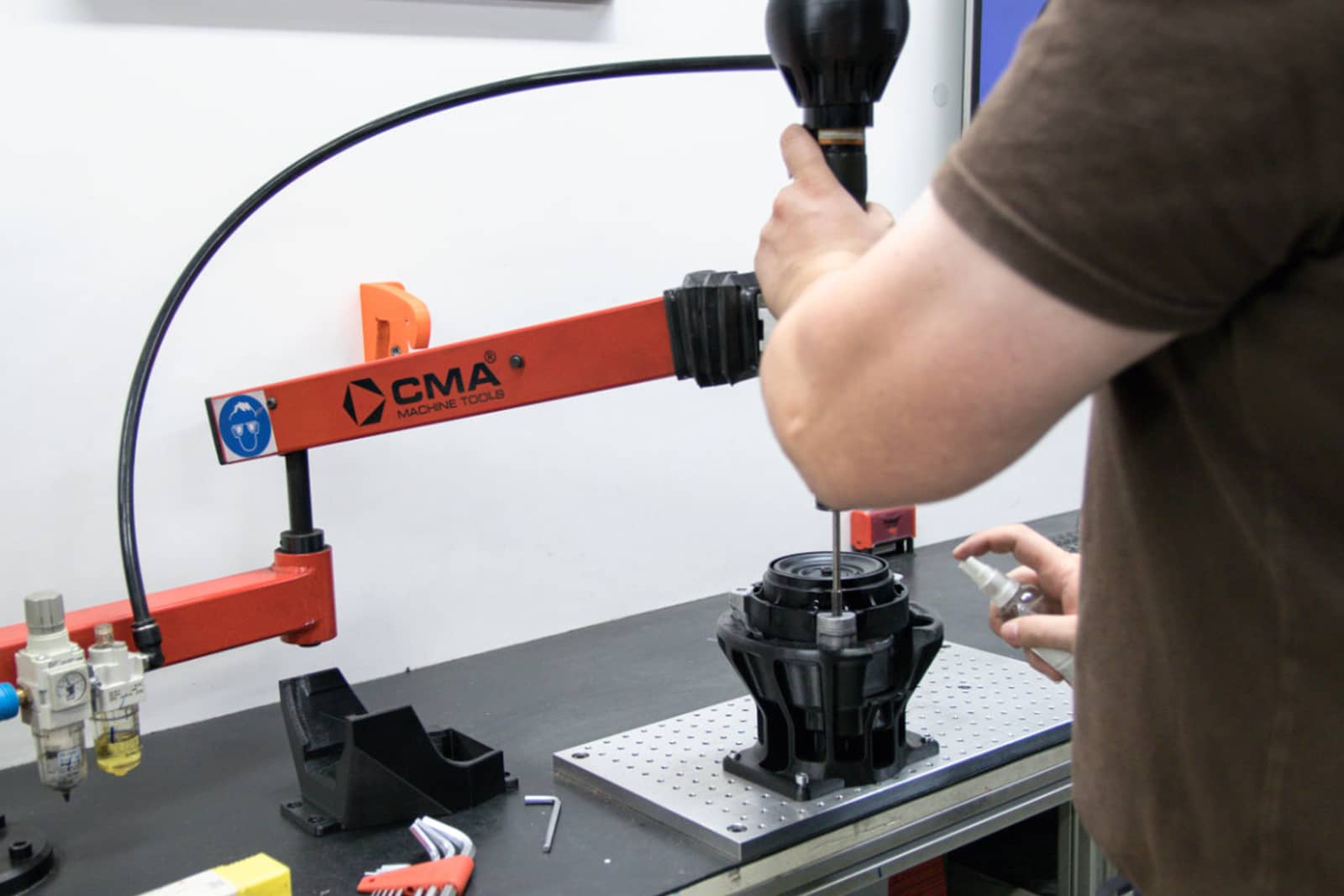

Automotive engine seating QC jig

Accelerating and simplifying QC in automotive production

Material: PLA (Fillamentum), Printing time: 27 h 11 min, Dimensions: 180 x 166 x 120 mm

Bed for mounting aluminium components on the laser station

The next day after receiving the requirements from the client, the component is ready for the production line

Material: PLA (Fillamentum), Printing time: 15 h 58 min, Dimensions: 290 x 100 x 60 mm

"A lot of things can be tested with very little cost, and that's what we need. To limit the cost, to be fast in those solutions, to be able to try it out very quickly, to test it in operation and draw a conclusion."

Jaroslav Kaplan, Toolshop leader in JTEKT

TRILAB 3D printers

TRILAB DeltiQ 2 Plus

Print up to 50 cm high models including flexible materials

TRILAB AzteQ Industiral

Large models from advanced technological materials.

TRILAB AzteQ Dynamic

Ideal workhorse for high-volume printing.

We can help you implement 3D printing

Contact us and our 3D printing experts will discuss with you:

1. Identify applications

2. Choose the right material

3. Knowledge to operate a 3D printer

4. Calculate cost savings