LASVIT: How 3D Printing Is Helping to Create Gorgeous Lighting

LASVIT is a Czech glass and design company with international renown, specialized in designing, developing, and custom-producing mainly luxury-class lighting installations. You’ll find LASVIT’s works in such places as the lobbies of renowned hotel chains, privately and publicly owned palaces, and concert halls, as well as metro stations worldwide.

Even though the primary materials for these installations are glass and plastic, 3D printing also plays a significant role during the technical process for their production. Welcome to a place where DeltiQ 3D printers are frequently running for even a full 24 hours a day!

Karel Pěnička works at LASVIT as an R&D Design Engineer. We met with him at the company headquarters in Nový Bor over some samples that illustrate how 3D printing is a fundamental aid in the process of preparing lighting-installation projects.

3D printers are of excellent use in the prototyping of lighting fixtures’ technical portions. For example, after a new light-module holder that they’ve designed is 3D-modeled on a computer, they first print it on a TRILAB DeltiQ, and then immediately give it a trial run in connection with the given lighting module. When adjustments are needed—which happens all the time in new-product development—the new version of the holder is can be readied quickly. As Karel Pěnička himself says: “There’s no need to wait what’s usually twelve whole days until a prototype is lathed; this significantly speeds up development and reduces its costs.” That’s because there’s no room for mistakes in the real production that follows—for large installations, it’s not uncommon to produce even thousands of lighting modules.

Another use for the 3D printer is in directly producing parts used in lighting fixture production. If for example one of the parts changes in size during production for technical or logistical reasons, the TRILAB DeltiQ can be used to ready distancing supports or rings that prevent the need to re-manufacture the components.

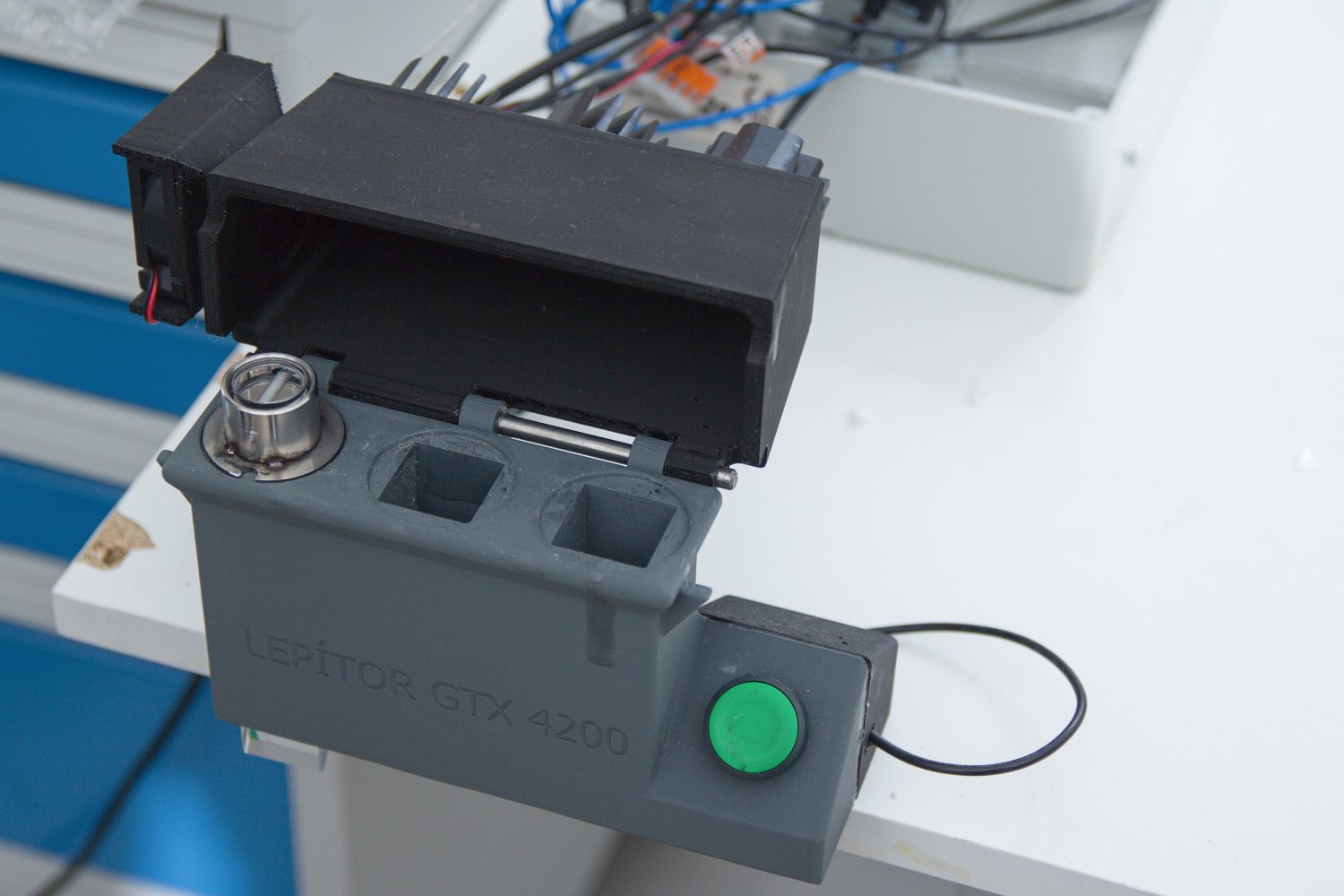

The DeltiQ also finds use in tooling. They’ve already used it to produce several jigs that have made it easier to bond steel and glass parts using UV-light curing. Jigs of this kind are completely 3D-printed. The printing material (the filament) is firm enough to secure the individual parts where they need to be and to ensure that their dimensions meet the required production tolerance. In the words of Karel Pěnička: “One day I designed it, the next day I printed it, and the third day we were already using the jig for bonding. With the total of four and a half thousand connections that we’ve got, this kind of tooling saves us a lot of time.”tří spoustu času.”

Besides these examples, prints from 3D printers are also used for producing male and female molds, small print runs of designer fixture elements, and models for parts that are not yet physically present in a project.

Pěnička states that the main advantage of the TRILAB DeltiQ printers—besides their uncompromising print quality and high printing dimensions—is the professional, and above all fast, printer support that is provided: “When I need advice, with TRILAB I can be sure that I’ll reach someone who understands both the printer and the print. With other manufacturers, that unfortunately isn’t typical.”