PILANA Machinery: Every Knife Model Saves Them Hundreds on Prototyping

PILANA Machinery, a member of the PILANA group, is specialized in the production of steel tools of the highest quality. Their main markets are in some of the world’s top economies—Germany, the USA, France, and the UK. Lasers, CNC grinders, lathing centers, and sharpeners are used for their high-precision manufacturing—and so is a TRILAB DeltiX 3D printer.

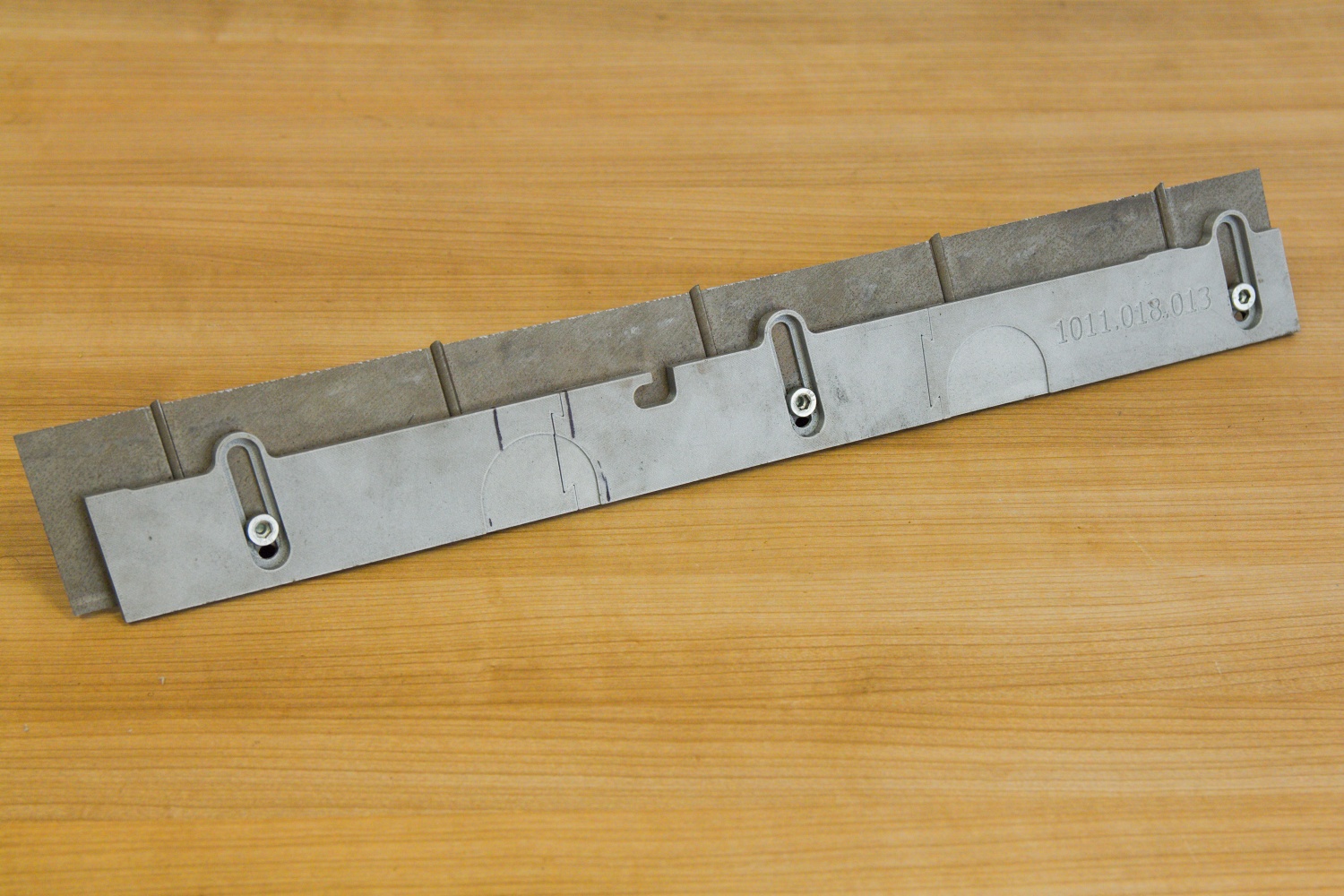

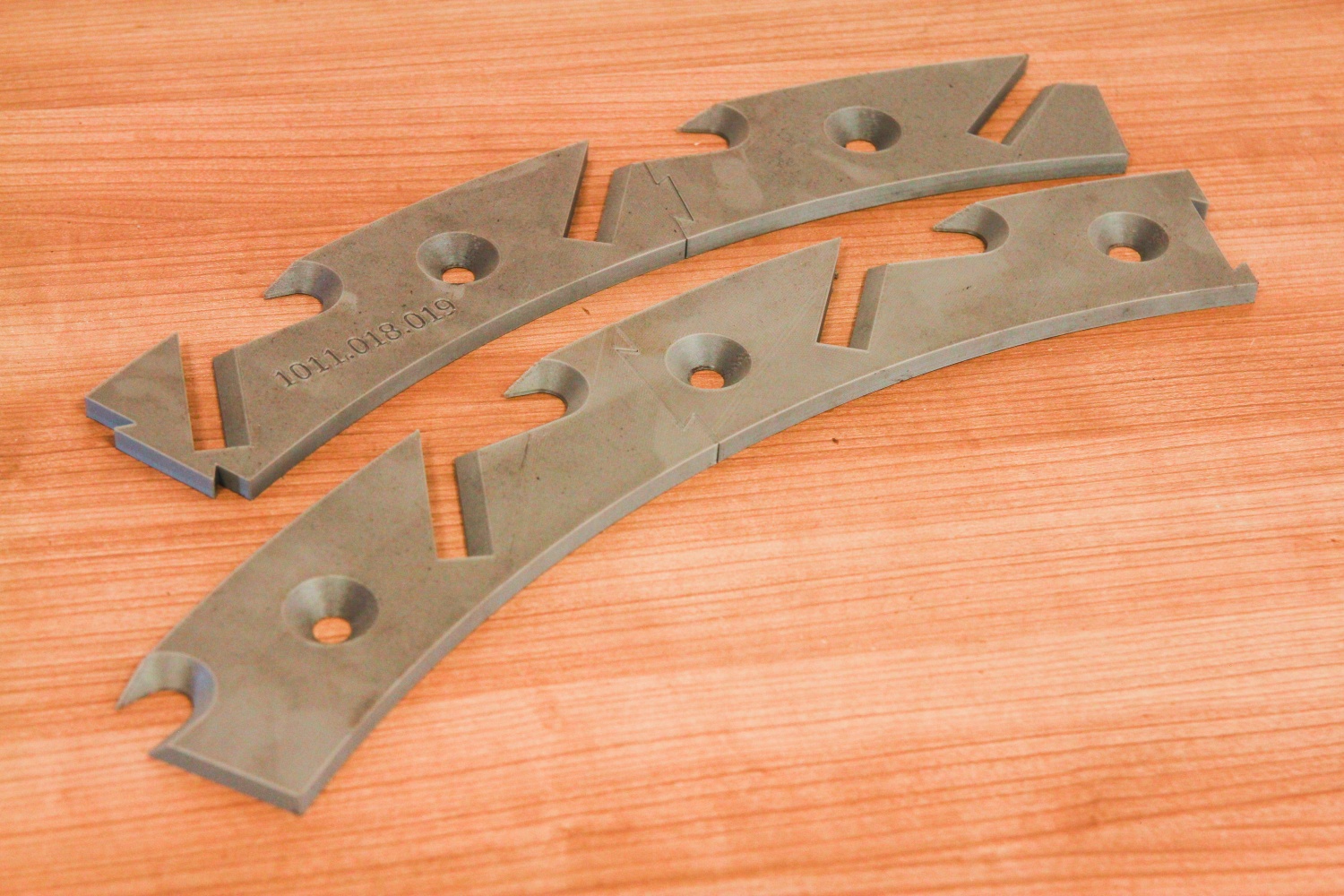

The company’s key product is knives for industrial machines that process wood or produce shredded wood for the furniture industry. PILANA produces knives for over fifty different brands’ machines overall. With such a broad portfolio, it’s important that every knife precisely matches the dimensions of the machines where it’s utilized.

Jan Polách is the head of their prototyping and structural-design workshop, and he’s also PILANA’s product specialist. He describes how the TRILAB DeltiX 3D printer has, among other things, significantly sped up their order execution: “We model a knife according to the specifications we’re given and then print it in a few hours on the DeltiX. This model is usually handed to the customer so that they can mount it onto their machine and check its dimensions. Once they’ve approved it, they have the real version of the knife produced from the material of their choice.”

Before PILANA deployed 3D printing, producing testing samples meant having to hook in their CNC machines and produce a metal model, which was time-consuming and above all vastly more expensive.

But prototyping isn’t the only way that 3D printing gets used at PILANA Machinery. 3D printing is also very financially attractive for them in tooling and more. For example for the printing of tools (i.e. special separators, lids, stoppers, meshes, etc.) for manufacturing machines—tools that the company needs in the hundreds per year: “In the past, we ordered all of these things as custom products from an external company, but this was a huge cost every year: tens to hundreds of thousands of crowns. Also, the production time was on the order of six weeks. Once our TRILAB 3D printer arrived, we could start preparing equipment like this and printing it on the fly and on our own to match our specific needs, and so our printer basically paid for itself immediately,” states Polách.