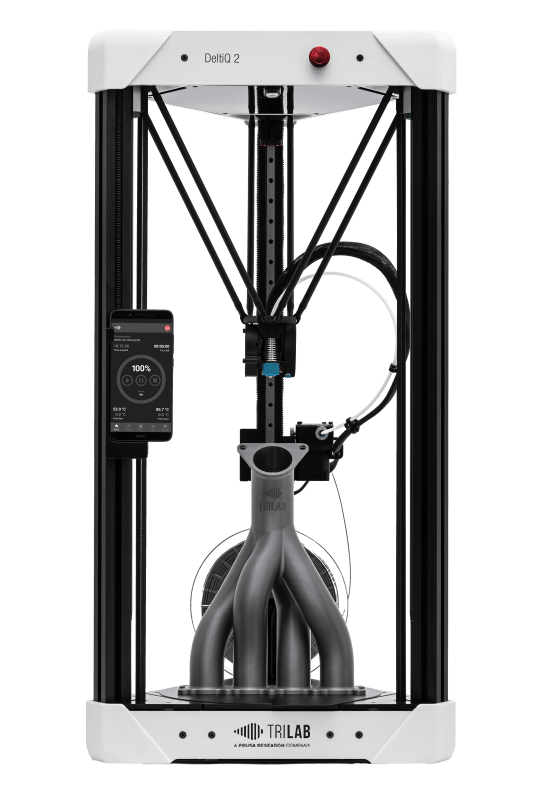

TRILAB DeltiQ 2

Different at First Sight

.. and not just in its looks. The TRILAB DeltiQ 2 is a reliable printer made with high-quality parts that’s used for professional printing in business and in the lab.

6 reasons to get the TRILAB DeltiQ 2

1 Top-notch prints

The model is static during printing, which results in perfect quality print over the entirety of the model’s height.

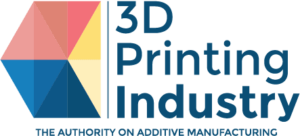

2 Unconventional

Unconventional and unexpected model orientation can be safely printed for an even better surface quality.

3 Complete solution

A tuned printer for professionals, a complete made-to-order package — starting from a demo print, a suitable configuration proposal, delivery with installation to service and application support.

4 Universal

You will be blown away by the range of materials that can be processed by this printer - from common filaments, to modern and advanced materials such as composites or flexibles.

5 Smart

Control the printer according to your needs - with your hand, using the DeltaControl wireless display, using our app in your smartphone or remotely using the WebControl interface.

6 Beautiful

As a unique industry standout, you’ll have trouble keeping your eyes of it thanks to the grace of the delta movements.

Reviews of TRILAB DeltiQ 2

„TRILAB DeltiQ 2 – A masterclass in delta FDM 3D printing.“

„If you're looking for a professional 3D print solution, then the Trilab DeltiQ 2 is incredible.“

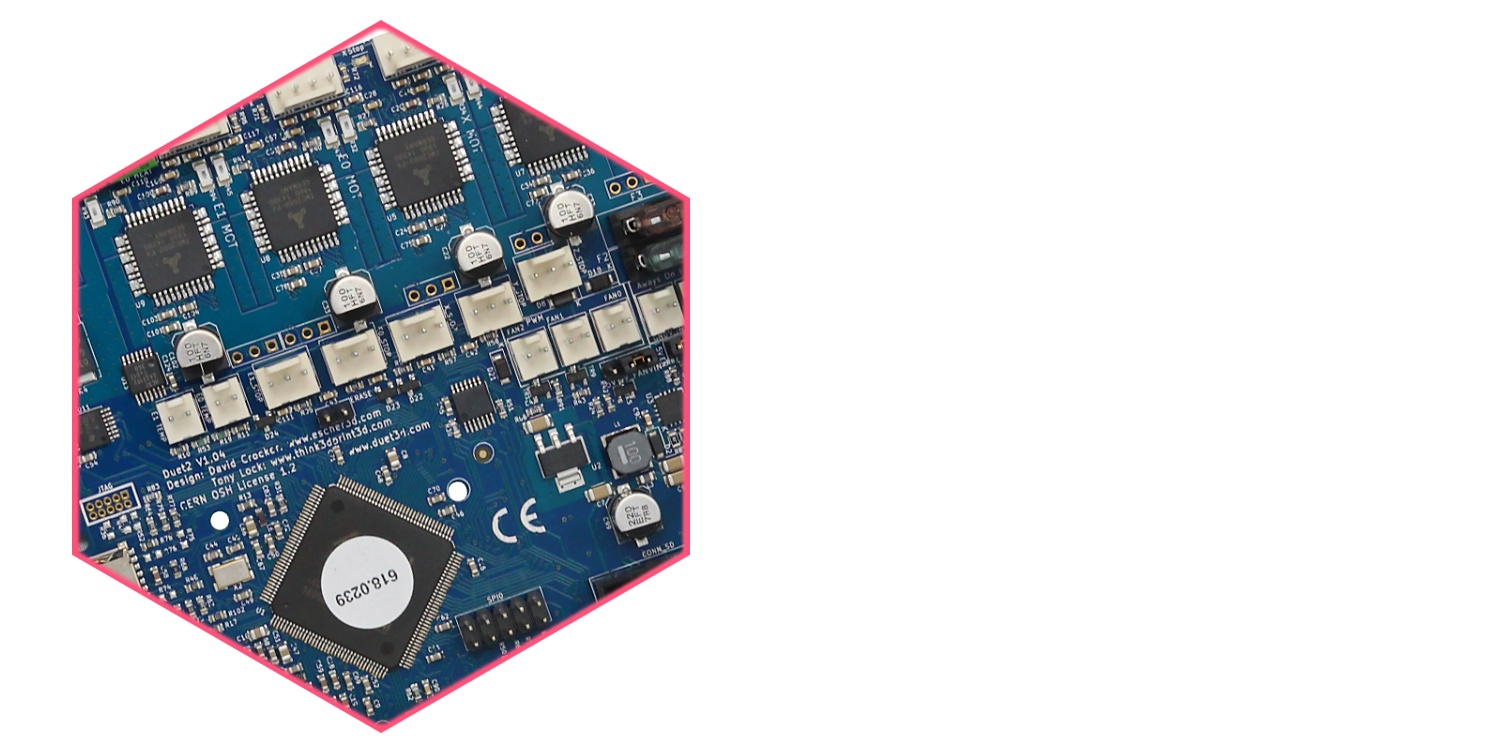

Made from the best parts

A support you can depend on

We do not produce thousands of printers. As a result, we guarantee exquisite product support to every customer worldwide. Something other vendors can only promise and HARDLY deliver.

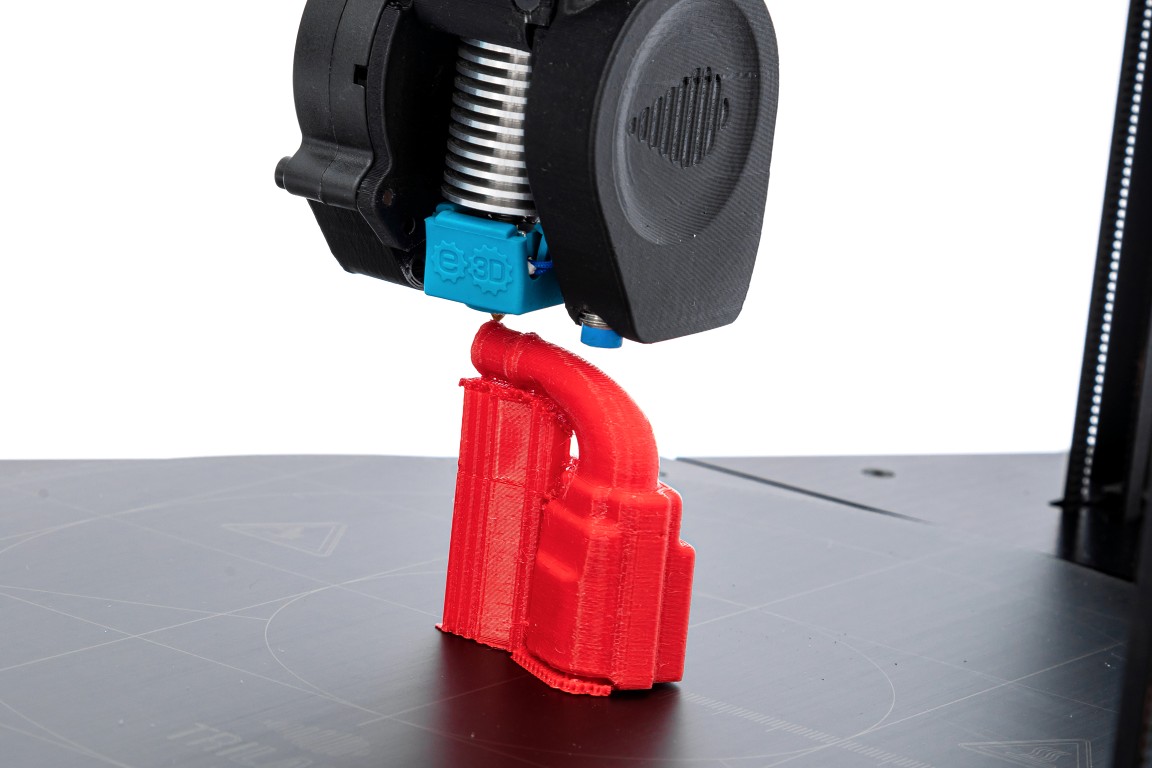

Print anything

With DeltiQ 2 you are unstoppable in your pursuit for perfect prints. Wide palette of supported materials, two perfect extruders and stimulating freedom of the print orientation. That's what conjures a smile on your face.

Standard models and materials

Standard models from PLA, PETG or CPE materials printed on DeltiQ 2 with ease, fast and in perfect surface quality.

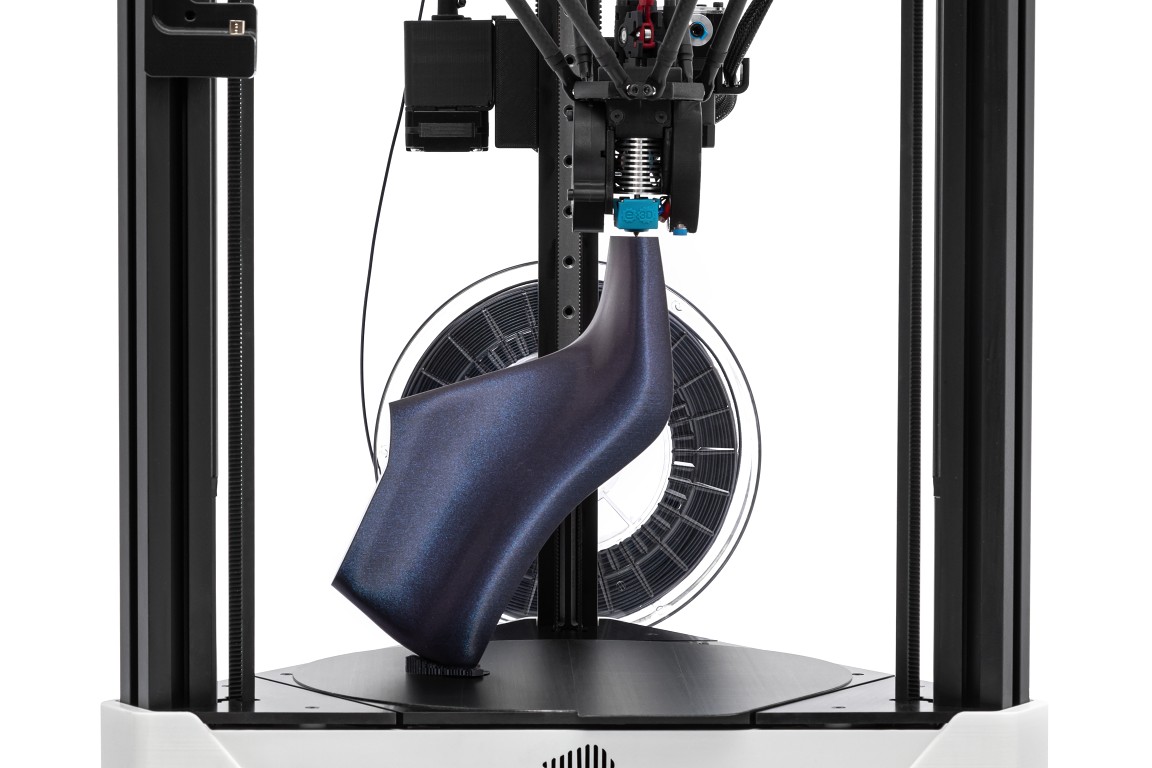

Bigger and difficult models

Bigger and more difficult models from PLA, PETG or CPE, printed on DeltiQ 2 without or with limited need of supports from the same material.

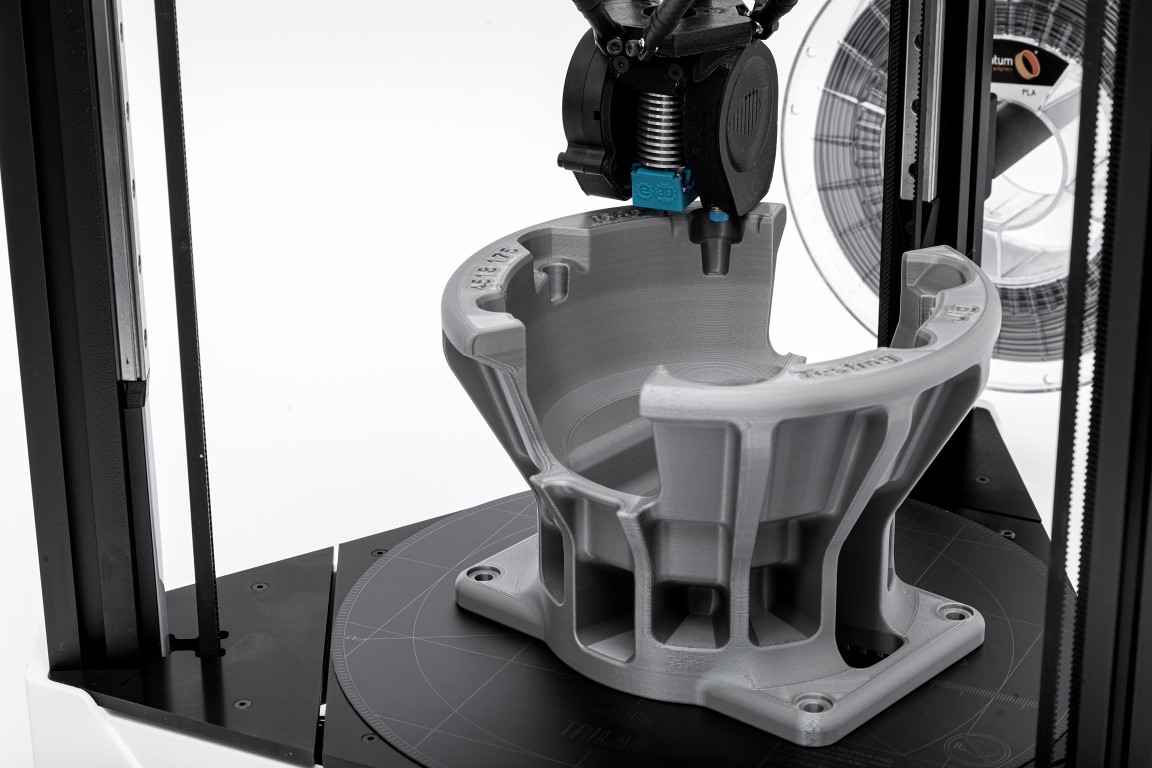

Technical and composite materials

Models from technical materials like ABS/ASA, Nylon or Nylon with CF printed on DeltiQ 2 simply by using hardened nozzle.

Flexible materials

Printing from TPU or TPE is piece of cake using unique delta printer - TRILAB DeltiQ with FlexPrint extension.

Wax filaments

Positive models for the subsequent production of precision casting molds, simply printed on DeltiQ 2 using wax or PMMA filaments.

They trust our printers

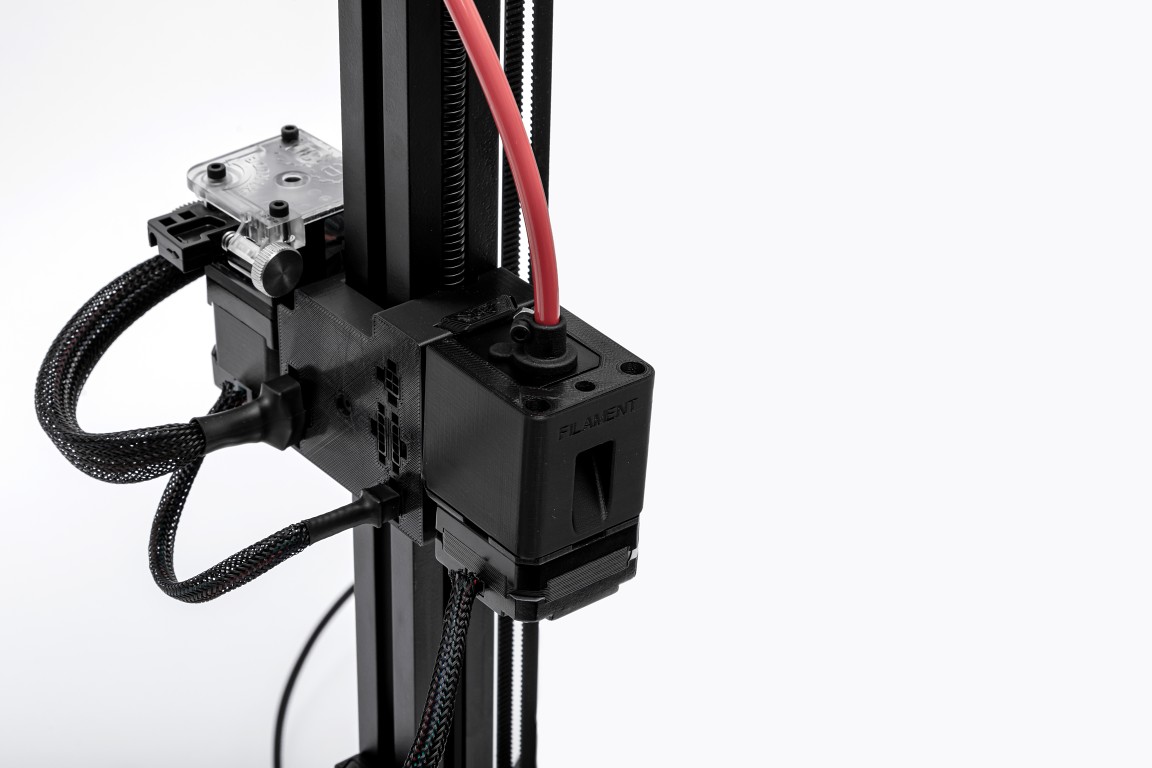

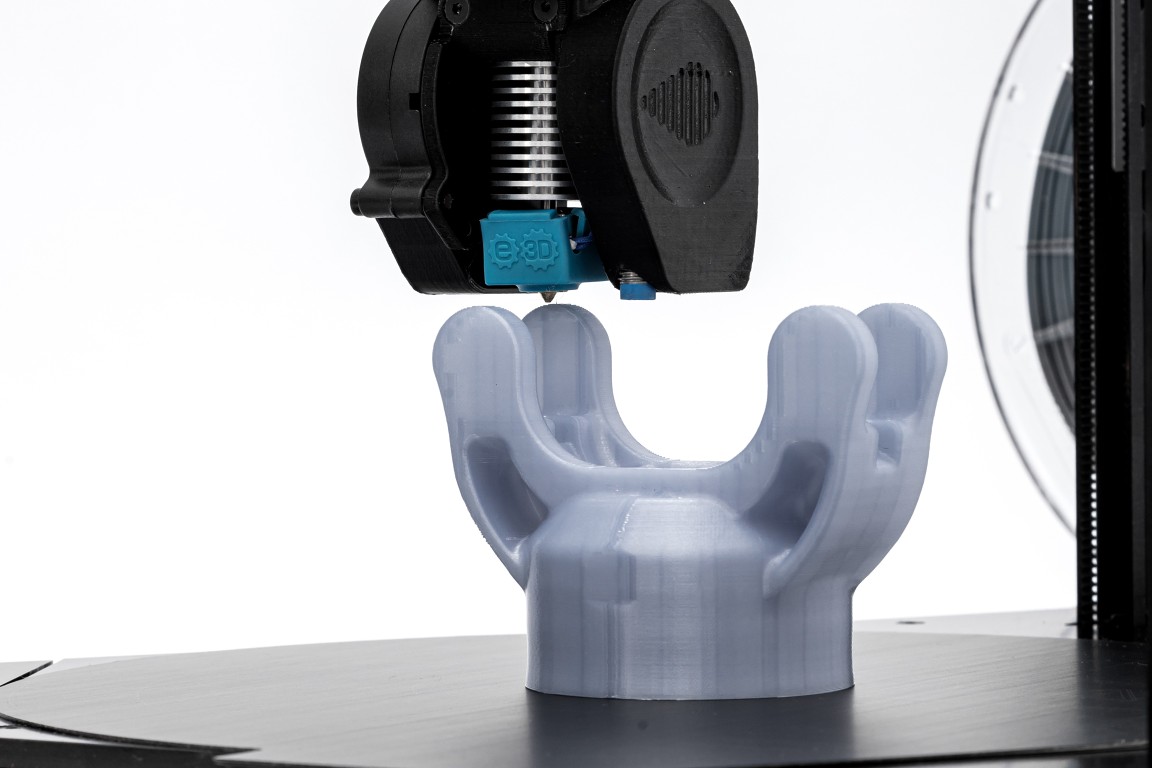

TRILAB FlexPrint 2

Printing from TPU or TPE is piece of cake using TRILAB DeltiQ 2 with FlexPrint 2 extension. With a unique remote direct drive extruder your TRILAB DeltiQ 2 will be able to print even the softest flexible materials with no hassle...

TRILAB unique remote direct drive is the optional addon. But hand on hearth – you will love this solution from the start!

A right fit for every project

TRILAB DeltiQ 2 (no longer available)

Standard model with a decent print volume.

TRILAB DeltiQ 2 Plus

Extended model with much bigger print volume.

Printer Specifications

Printer Specification |

|

|---|---|

| Print technology | Fused Deposition Modelling (FDM) |

| Print Volume | DeltiQ 2: Ø 250mm (X, Y) × 300mm (Z) DeltiQ 2 Plus: Ø 250mm (X, Y) × 500mm (Z) |

| Printhead | Light printhead; E3D V6 all-metal hotend; Easily swappable as a complete assembly |

| Extruder | E3D Titan geared extruder, bowden setup Optional “FlexPrint Edition” - Zesty Nimble extruder for demanding and flex filaments |

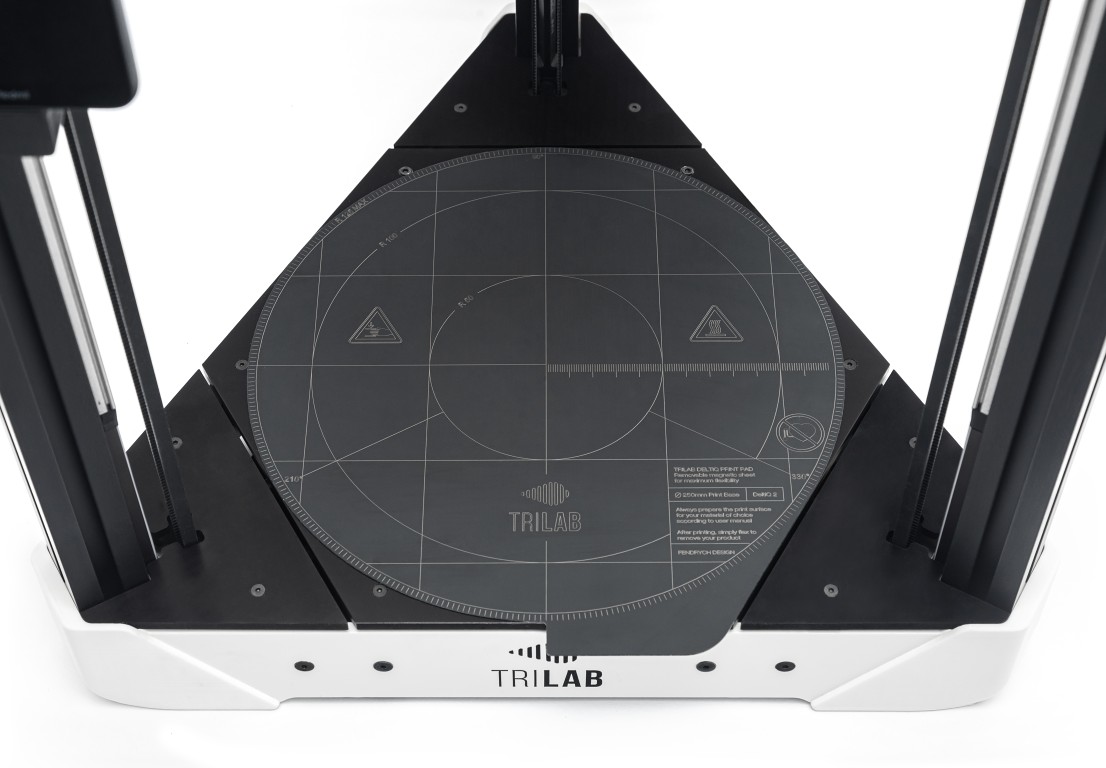

| Print Platform | Massive, 5 mm thick aluminium heated print base Swappable magnetic PrintPad sheet with PEI surface PrintPad sheets with alternative surfaces available |

| Control interface | Wireless 5.45“ IPS “DeltaControl“ display, incl. charging dock DeltaControl app; iOS/Android WebControl interface; PC/Mac |

| Connectivity | LAN or WIFI with local or remote access 3x USB: WIFI/LAN module/USB drive/Webcam/Palette 2 |

| Print Monitoring | Multicolor LED indicator for visual print status overview Built-in camera with print illumination |

| Supported input formats | STL, gcode; standard slicers (Kisslicer, Cura, PrusaSlicer, Slic3r, Simplify3D) |

| Operating printer temperature | Recommended printer operating temperature is 20 - 32 ° C (68 - 90 ° F), storage temperature 0 - 32 ° C (32 - 90 ° F) |

| Dimensions and weight (printer) |

DeltiQ 2: 41×50×81 cm / 10 kg DeltiQ 2 Plus: 41×50×98 cm / 11 kg |

| Dimensions and weight (whole package) |

DeltiQ 2: 49×53×105 cm / 18 kg DeltiQ 2 Plus: 49×53×105 cm / 19 kg |

| Power | Input 100-240 V, Output 24 V, 250 W |

Print Output |

|

|---|---|

| X/Y resolution | According to the used nozzle in the range of 0.25-1.2 mm, standard 0.4 mm |

| Z resolution | A layer height of down to 50 microns, maximum layer height depends on the used nozzle |

| Maximum nozzle temperature | Standard up to 300 °C |

| Maximum print bed temperature | 105 °C |

Materials |

|

|---|---|

| Filament diameter | 1.75 mm |

| Compatible materials | Standard: PLA, PETG/CPE, ABS/ASA, PETG-CF, PC, PP, PVA, BVOH, PACF, PAGF FlexPrint extension: nylon/PA, flexible materials (TPE, TPU) |