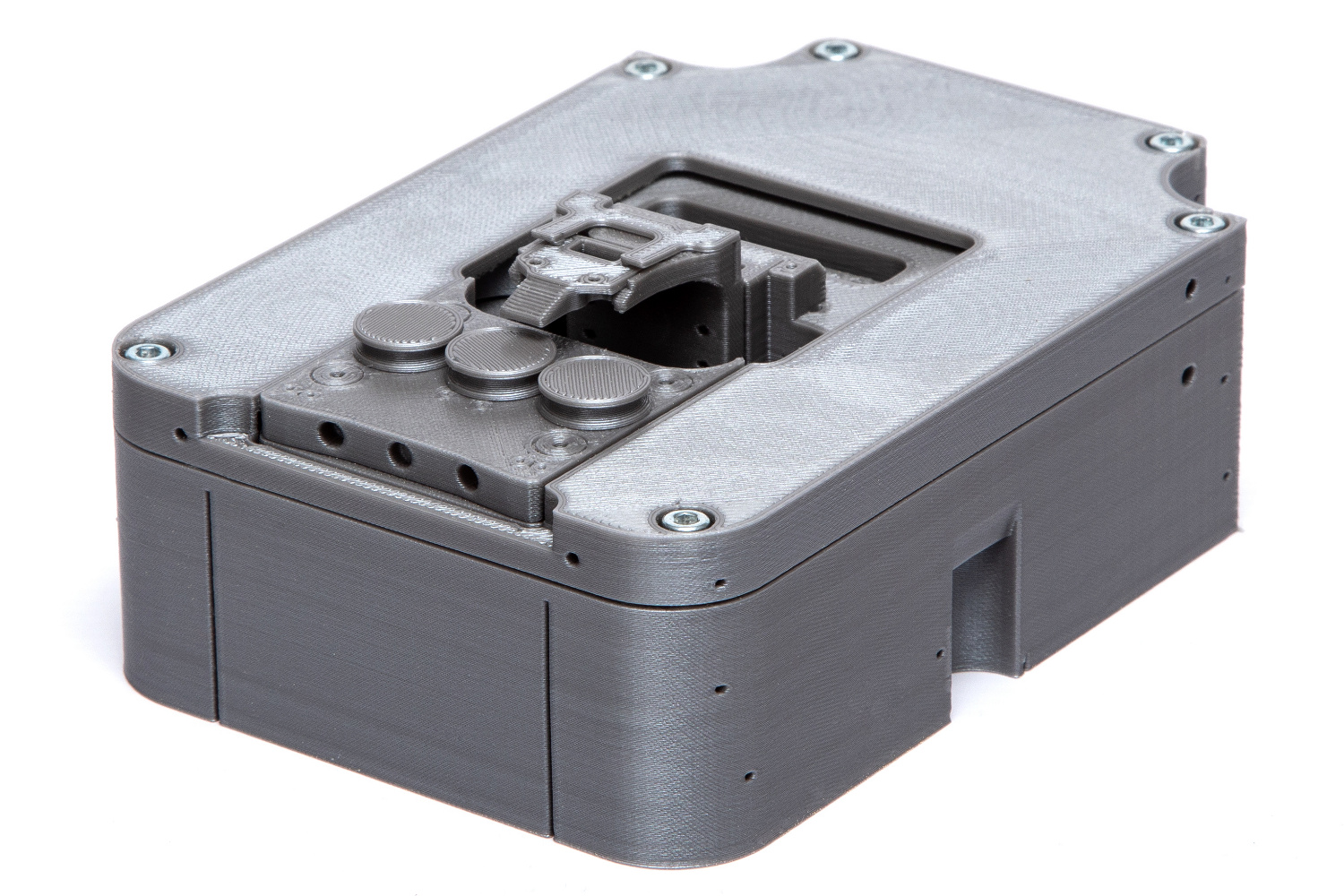

NenoVision: 3D printing lets you touch our microscope safely

NenoVision is a startup from the CEITEC Central European Technological Institute, and is one of the “incubated” firms at the JIC INMEC South Moravian Innovation Center. It boasts the LiteScope—one of the only microscopes in the world that can combine data from an electron microscope and an atomic-force microscope and assemble it into 3D models. This literally opens up a new dimension in research.

Nenovision has found an application for 3D printing in solving the tricky problem of how to enable partners, customers, and interested experts to “touch” the microscope: “The LiteScope normally runs in a controlled environment, and moreover in a vacuum, and it’s a sensitive and very expensive instrument. So unfortunately, neither we nor our distributors can take it to all the events and trade fairs where it needs to be seen, nor can we offer it to partners so that they can test how it will fit with their machines,” explains Jan Neumann, the owner and CEO of NenoVision.

The actual process of lathing the microscope’s individual parts is so costly that not even the production of a copy of the device without “live” parts makes financial sense. In the end, it was none other than 3D printing that showed itself to be an elegant solution: “Because the complete 3D model for production was already finished, it was enough to prepare it and print it on a TRILAB DeltiQ printer, and make our device mockup a reality. Now we can easily produce copies and show them to customers and the public, at just a fraction of the usual cost,” Jan Neumann adds.